Moutardi in figures:

Years of experience

Satisfied Clients

Deliveries made

Pallets produced

Founded in 2005, in over 14 years of activity, our company has made a name for itself on the pallets end euro pallets market through seriousness, professionalism and superior product quality. Since the beginning of its activity, Moutardi SRL has tried to understand as best as possible what the customer really needs and to constantly adapt its activity and resources in this respect.

During its existence, our Company has gone through two major stages of retrofitting and reorganisation to align to the latest standards in the field, so that, at this moment, we work with state-of-the-art machinery, we have a team of qualified and experienced workers in the field and we offer the client an unbeatable good value for money.

In addition to our products, we can also offer you the following services:

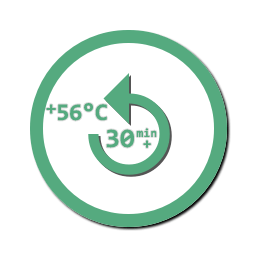

Heat treatment

We can heat treat wood according to the ISPM15 standard (½ hours at +56 °C). We are ISPM15 licensed, with code RO-CS-26.

see details here

Wood drying

We own a high capacity industrial dryer and we can dry wood to the moisture content required by the client in a short time.

see details here

Transport

If our client requests, we also can provide transport for our goods, both in the country and abroad.

see details here

Product development

If a customer has a technical drawing for the pallet, this first step is skipped. Otherwise, on request, we offer professional services for pallet design. This first step includes collecting information as objective as possible about:

- Client’s industry

- Client’s products

- Type of storage

- Storage conditions

- Handling

- Transportation

- Packaging

- If the pallet needs to be heat treated

- If the pallet needs to be dried

- If the pallet will be recovered or not

- Number of uses

- Other special requirements

Based on this information, the pallet is designed and the technical drawing is made, see more details here .

The first step in our manufacturing process includes preparing and cutting logs to make pallet components: boards and blocks (feet). This first step includes, as the case may be:

- Log trimming

- Log debarking

- Log cleaning

- Log washing

- Band saw cutting

- Pendulum circular saw cutting

- Multiblade circular saw cutting

- Simple circular saw cutting

- Board sorting

- Block sorting

- Pallet component stacking

- Quality check

More details about our log preparation and cutting process can be found here.

The second step in our manufacturing process includes the actual assembly of the pallet and, as the case may be, its treatment or drying. This first step includes, as the case may be:

- Board sorting

- Block sorting

- Debarking

- Sawdust cleaning

- Material arrangement

- Nailing

- Chip removal

- Board grooving

- Block stamping

- Stacking

- Banding

- Quality check

More details about our pallet assembly process can be found here.

When a client wants the ordered products (either pallets or timber) to be heat treated and/or dried, the manufacturing process also includes the following steps:

- Dryer sterilisation

- Dryer loading

- Dryer heating

- Keeping at the optimum temperature

- Electronic monitoring

- Repeated checks in the chamber

- Air temperature measurement

- Air humidity measurement

- Wood temperature measurement

- Wood moisture content measurement

- Automatic chart recording

- Issue of documents for the client

More details about our heat treatment process can be found here and about wood drying can be found here .

We offer our clients, on request, transport in the country and abroad. The merchandise is usually packed for shipment according to standard principles in the field or specific principles, if there are special requirements from the client regarding the packaging. These two stages include:

- Collecting information about packaging

- Collecting info. about the transport

- Packet volume calculation

- Stack / lorry calculation

- Tonnage estimation

- First transport simulation

- Simple packaging (straps)

- PP strap packaging

- Metal sheet band packaging

- Transport contracting

- One last qualitative check

- Loading in the lorry

More information about transport and packaging can be found here.

“The forest is a renewable and infinite source of logs if it is respected and the log is cut when it should be and how it should be cut!” Read more…

Sorin Ciurca

Commercial Manager – MOUTARDI

MOUTARDI IS A QUALITY SUPPLIER

Choose to work with us and we offer:

Quality, Reliability, Professionalism, Experience in the field, Customer orientation, Flexible prices, Unbeatable good value for money.

Where to find us:

Company name: S.C. MOUTARDI S.R.L.

Reg. no.: J11/1087/2005

VAT no.: RO18215584

Registered office: str. Trandafirilor, nr. 11, or. Baile Herculane,

jud. Caras-Severin, Romania

Postal code: 325200

Address of our plant: Iardastita FN, com. Toplet, jud. Caras-Severin, Romania.

Postal code: 327400

Location of our plant on the map: