ISO 9001

Pallets, EURO pallets, Timber and Firewood at the highest quality standards!

A first level of quality in our products comes right from our vision on production and how the raw material - the log - is made profitable. This profitability comes from the fact that, before entering production, the log is sorted into three quality levels (A - superior, B - medium and C - inferior) and it is used in the most appropriate way for each product category, namely: the best quality logs (class A) go to timber, but also to high quality pallets, class B logs go to pallets and euro pallets B and class C ends up as firewood. Basically, our company offers three categories of products that cover the three quality levels of the logs so that the log of a certain quality reaches exactly those products where, after being processed, the appropriate quality can be obtained at a well-optimised cost. Thus, a client will receive the product at the best price for the desired quality.

Product quality and service quality, the quality of relations with clients and potential clients are paramount for us. Although it has an internal quality management system, our company has successfully documented and implemented the external quality management standard SR EN ISO 9001:2015.

The implementation of this external quality management standard also came from a desire to assess and improve already existing internal procedures, but also to find new more efficient work methods and procedures, as well as to improve and deepen the collaboration between departments, namely:

- increasing customer satisfaction both in terms of products and services purchased from us and in the relations with the company's employees before a purchase, during a purchase and after a purchase;

- implementation of dedicated, personalised quality management methods for each product category: pallets, timber and firewood;

- improving and streamlining production processes;

- preventing non-conformities and minimising non-quality costs;

- improving internal audit methods and implementing other types of external audit;

- regular training of the company staff to eliminate non-conformities found;

- regular assessment of the management by external accredited appraisers to ensure a modern management, according to the changes and the realities of the market that have occurred over time;

- implementing new sensors, devices or machines to permanently monitor production and alert the company's management when non-conformities are detected;

- regular collection of quality-related feedback from clients, its analysis by the management and improving the necessary processes in accordance with possible dissatisfactions, but also with the actual expectations of clients;

ISO 14001

Care for the environment, care for the future generations!

Taking into account especially our field of activity - Wood cutting and planing (namely firewood and timber), but also Manufacture of wooden packaging (pallets and EURO pallets) - we understand the importance of environmental aspects and we pay increased attention to measures related to reducing as much as possible the processes that could lead to environmental pollution.

The most important measure taken in this regard, a measure that is actually embedded in the our vision and to which attention has been paid since the company was founded, is a measure related to procurement - namely, that our company buys logs only from 100% renewable and sustainable sources. Only suppliers who share and respect this common vision are accepted to supply us with logs. This procurement is a basic principle in our company's relationship with the environment because we understand that forests are an important pillar for the environment and forest exploitation must be done so that we, the people, can use the wood provided by forests, but without affecting their global ecosystem, without reducing the level of wood mass in the forests, but on the contrary, increasing it. When we do not exploit more wood than the forest can give us and only mature wood, towards the end of life, we make sure once again that we have a renewable and infinite source of wood mass and offer future generations a clean environment, with forests that do not decrease, but increase in volume and surface area. More details about our vision regarding our log procurement can be found on this site on Our Vision page, Our vision on log supply section.

Moreover, by implementing the SR EN ISO 14001:2015 standard, our company has re-assessed and improved all aspects related to:

- proper management of the waste resulting from the general activity of the company;

- reducing the consumption of energy and resources with the help of new emerging technologies;

- correlation of the company's activity in accordance with the environmental regulations in force;

- regular training of the staff to raise awareness of the need to reduce environmental pollution;

- regular internal audits related to the environment;

- analyses at management level to improve the company's entire environmental pollution management system;

- setting environmental goals for a well-defined period (monthly, quarterly, half-yearly, annually) and monitoring their fulfilment.

ISO 45001

Health and safety first!

Log processing is the basis of our activity and, for our company, this means cutting logs and converting them into products such as pallets or EURO pallets, timber, but also firewood. It is well known that log processing is not easy and not without hazards. We understood this and took it as seriously as possible from day one. As a result, our company has not had any major work accidents since its foundation.

Although it has clear well-defined and rigorously implemented internal procedures regarding the health and safety of its employees, our company has successfully documented and implemented the external standard SR EN ISO 45001:2018, both to improve procedures and to identify and implement new procedures related to health and safety at work. The most important aspects related to the implementation of this external standard, as well as its correlation with internal procedures, are:

- regular training of the company employees, both in-house and by a specialised company;

- testing and, as the case may be, implementing new safety procedures at work in production;

- abandoning sawdust evacuation from the production hall through the exhaust method (dust generators) and implementing a new sawdust evacuation method with conveyor belts;

- applying sensors, components or systems on all machines in the production hall to improve safety at work;

- carrying out regular internal or external audits to identify possible opportunities to improve aspects related to health and safety at work in our company;

- participation of the personnel responsible for health and safety at work in external courses and trainings organised by accredited and specialised companies.

ISPM15

Pest-free wood!

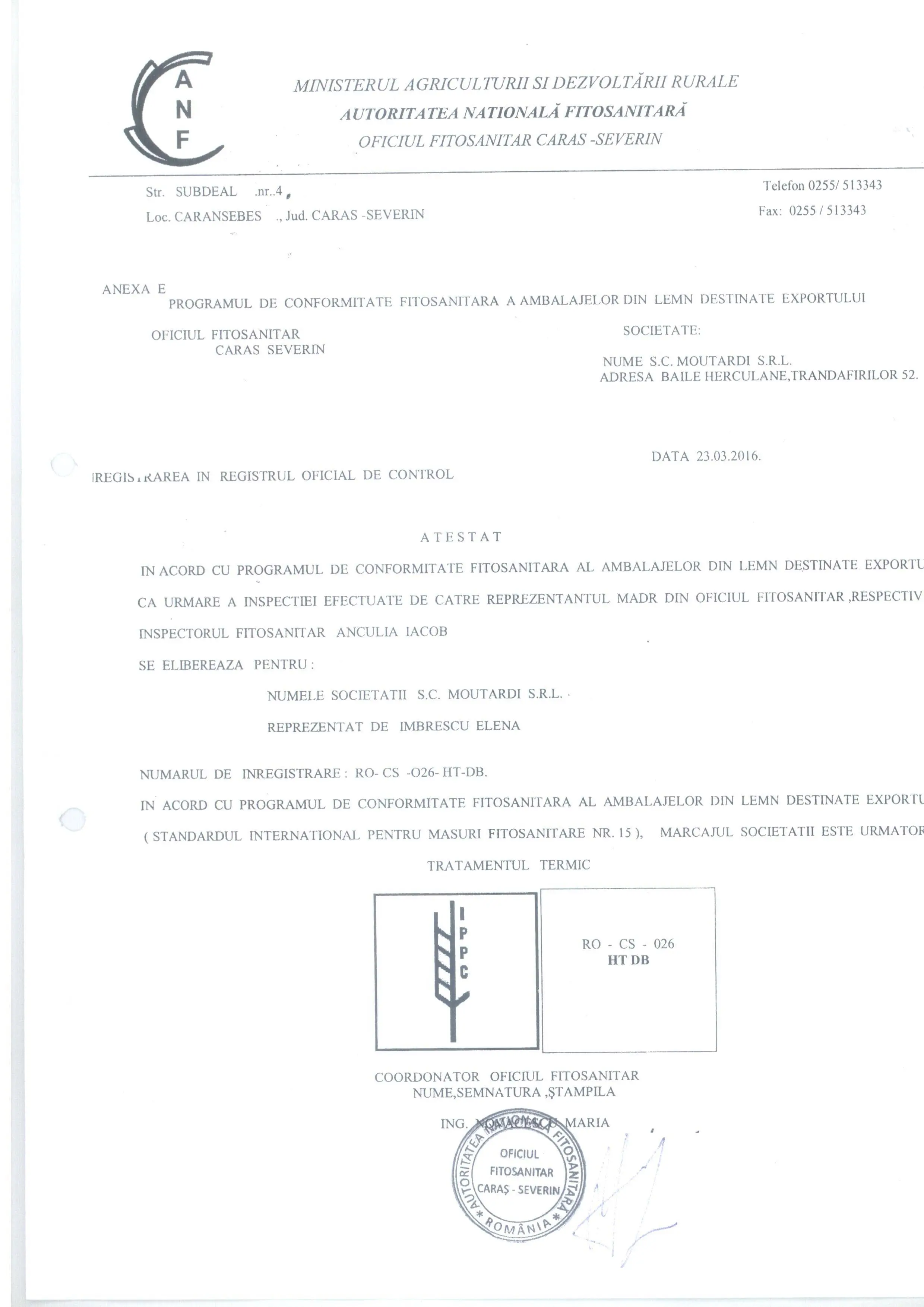

Both for PALLETS and EURO PALLETS and for TIMBER, our company is authorised by the National Phytosanitary Authority within the Ministry of Agriculture and Rural Development according to the international standard IPPC - ISMP15 for the heat treatment of wood, having company code RO-CS-026.

With this authorisation according to ISPM15, our products can go through customs outside Romania because most countries require wooden products to be free of pests when crossing borders.

To procure this authorisation, our company invested in a modern, high-capacity industrial dryer and in the technology and software for heat treatment applied to wood not only to meet the regulations of the phytosanitary authority, but also to become modern and efficient at a low cost.

Read more about our heat treatment applied to wood.